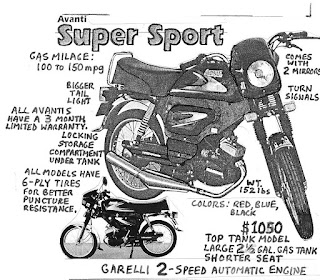

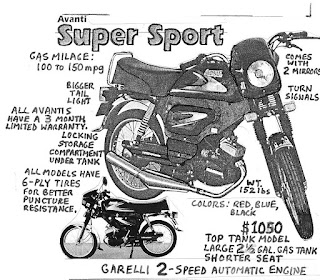

Here's the new project. This 2001 Avanti moped from Monto Motors Limited (Rajasthan, India) was in a friend's collection, and it recently became available for adoption. This is similar to the Cosmo Motors of Pennsylvania also used Monto Motors to produce the Avanti moped once again and distribute the Cosmo Stinger which was a copy of the Avanti Super Sport. The moped uses a Garelli VIP engine, and has the two-speed automatic transmission. Our friend said this was a very reliable machine, and it actually has over 4000 miles on it to prove it. It has some modifications (a 70cc kit, right-side, inlet manifold, and non-stock carburetor).

This moped is a tubular frame construction, with a top-mounted fuel tank, just like a little motorcycle. It holds 2.5 gallons of pre-mix fuel for a very long range machine! It is a lightweight, attractive-looking modern moped. Its been re-sprayed at least once and will need refreshed for appearance. The body panels and seat are easily removed for cleaning and paint prep. The tires are original and will need replacement.

A morning with a toothbrush and some cleaning solution have removed twenty years of grit and grime from the frame and chassis. A certain future-rider got his hands dirty in the cleaning process.

The mechanical issues are few. It is well made, and the electrical system is functioning. One operational problem is the shift point from 1st to 2nd gear. The engine has plenty of torque in first gear. It would wind out much higher in RPM before it really needed to go to 2nd gear. However, the transmission shifts into 2nd way too early and starts bogging. We are eagerly awaiting new "Double Duck" clutches with a higher durometer material to go into production. I suspect that the original rubber clutches have swollen and don't shift at the right points.

The handlebar clamp was a little concerning. The wrong bolts were used at one point, and the casting was not looking great. I fashioned a stainless steel cover to act as a washer and provide extra strength to the casting.

A leak in the fuel tank was discovered. It was just a little weep. A repair had been attempted using some polymer material, but that had already degraded. Luckily everything was clean, and only required some roughing up and de-greasing. I've used this trick before to seal up pinholes in gas tanks, and it works very well. I got my biggest soldering iron, and some good flux and just soldered up around the whole mounting bracket. (Yes, solder will stick to very clean steel) No more leak.

The general condition of the bike was "barn fresh" when we picked it up. Parts had been re-sprayed at some point, and just didn't look good. A new color was decided upon, and we went into full paint of the blue body parts into a new color. We think it is very 1950's retro.

PHBG 15

65 Main Jet

(Needle bottom notch)

262AU Atomizer

42 Idle Jet

60 Starter Jet

K&N Air Filter